Novelis PAE is currently building four new JUMBO 3CM® continuous casting lines, which are expected to be shipped later this year to two of its major customers. Gränges Americas A…

Flextreme™ is Novelis’ proprietary technology for continuous horizontal casting of ready-to-forge aluminum billets. This new technology decreases the cost, time, energy and CO2 emissions in the manufacture of forgings because…

Novelis PAE launched a new workshop for the maintenance of all its metal level sensors and actuators, including the latest Plug’n Cast™ generation upstream of Industry 4.0.Featuring an innovative, compact…

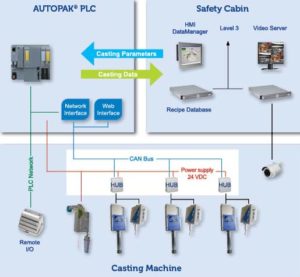

Author: Antoine Le Tullier, Novelis PAE, VoreppeNew generation of “Hands Free” Casting: AUTOPAK® Metal Drive System, Ready for Industry 4.0The development of hands-free automatic DC casting started at Novelis PAE more…

This new casting line is part of Gränges’ $110 million investment to expand production capacity in North America to meet growing demand for light-gauge foil, automotive heat exchanger materials, and…

Novelis PAE commissioned 4 additional continuous casters Jumbo 3CM® 2250 mm width at ASAŞ ALÜMINYUM in Turkey. ASAŞ ALÜMINYUM, the leading company in Turkey for the production of aluminium billets,…