Edge miller

The edge miller enables accurate in-line milling of strip edges to eliminate solidification heterogeneities on the edges. As a customer, you will benefit from:

Improvement in metal recovery: the cutting width can be easily adjusted and minimized, thus reducing the amount of scrap.

Reduction in the number of edge trimming operations during subsequent downstream rolling: the quality of the edges makes it possible to roll down the strip to around 0.3 to 0.4 mm, depending on the alloys.

Compared to trim cutting, milling does not damage strip edges, nor does it create any stress in the material. It is also easier to adjust, even during casting, and is less noisy.

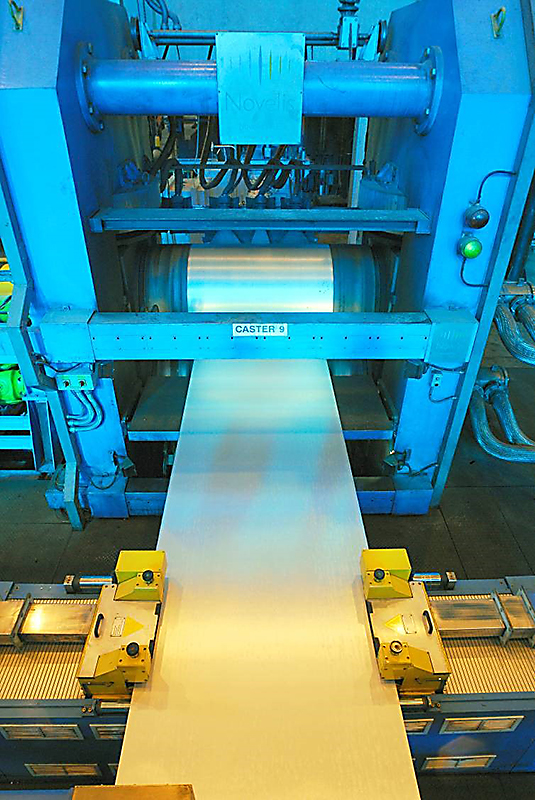

The milling equipment is located just downstream of the casting rolls and before the shear.

The equipment comprises two independent milling units (one on each strip edge), positioned and secured to the floor in function of the maximum casting width.

The edge miller can be installed on any type of continuous caster, horizontal or tilted, and many retrofits have been successfully implemented over a period of more than 20 years.

Chip recovery

The two milling heads are connected to a chip extraction system that collects and conveys the chips by suction to a recovery bin.

The chips can then be compacted by a scrap press and loaded into the melting furnace for easy recycling.

What you get

when you choose

the Novelis PAE

edge miller:

- The product of a wealth of experience and technological leadership

- Novelis PAE’s ability to design and supply the whole casting line (located downstream of the holding furnace): degasser, filtering unit, launder system, casting machine

- 60 years of experience serving aluminum casthouses

- Unique engineering know-how to match your specific needs and requirements

- Technological advantages, resulting from our first class innovation policy

- Extensive operational experience and a real understanding of the needs of users, helped by the fact that our own group is among them

- First-class customer support and service worldwide